Abstract

Perennial groundcover (PGC) has promise as a scalable approach to generating natural resource benefits and sustainable biofuel feedstock while preserving the high yields of annual row crop production. Partnering row crops with temporally and spatially complementary low-growing, shallow-rooted perennials, such as Kentucky bluegrass (KBG) (Poa pratensis L.), is one example of an emerging PGC system. PGC’s ecosystem benefits can only be fully realized if commercial-scale adoption occurs, which hinges on its economic feasibility. This paper utilizes an enterprise budget framework to detail and compare the expected cost and revenue of establishing and maintaining PGC in row crop systems with standard continuous corn (SCC) (Zea mays L.) production, including stover harvest, but excluding economic incentives for ecosystem services. Optimistic and pessimistic assumptions were used, along with Monte Carlo simulation, to characterize the uncertainty in results. In the optimistic stover market scenario, Year 1 net returns for PGC averaged USD 84/ac less than for SCC; Year 2+ net returns averaged USD 83/ac more, meaning that cost parity with SCC occurs by the second PGC system year. Without stover revenue, parity is achieved after five years. These results affirm that PGC’s economic viability is critically impacted by a groundcover’s lifespan, the yield parity with SCC, and the availability of a stover market.

Introduction

The increasing productivity of corn (Zea mays L.) farming practices in the Upper Midwestern US have resulted in increased acreage planted to corn [1], with nearly one-third of US cropland planted to corn each year. In corn systems, corn stover is the predominant biological material on fields post-harvest, through the ensuing winter and spring, until the next corn crop emerges [2]. Stover retention maintains soil organic matter [3], sustains long-term crop productivity by bolstering the soil structure [2,4,5], increases the water holding capacity for plant uptake [6], and decreases erosion [7], a process that threatens the global food supply by diminishing long-term soil productivity [7,8]. Conversely, stover removal increases corn grain yield in the short term until soil degradation lessens productivity [9] and is practiced on nearly one-fifth of corn acres [10].

While stover retention is critical for soil health, increased stover removal is expected due to the forecasted demand for sustainable aviation fuel (SAF). This demand necessitates soil conservation practices to facilitate greater stover removal and a low-carbon-intensity (CI) feedstock to ramp up SAF production from 24.5 million gallons consumed in 2023 to 35 billion gallons by 2050, while simultaneously decreasing the CI of SAF by 50% [11]. Corn stover is recognized as the largest single existing source of feedstock for this effort [12]. However, standard field practices influence sustainable stover harvest significantly and limit stover removal [13,14,15].

While cover cropping is an effective practice for natural resource conservation to facilitate stover harvest, annual cover crops comprised only 3.9% of the total US cropland in 2017, increasing to 4.7% in 2022 [16]. The limited deployment of annual cover crops is attributed to adoption cost barriers and risks associated with the practice, which can impede the cash crop [17,18,19,20,21]. Farmers who have adopted and discontinued annual cover crop usage indicate that the practice was not profitable and caused cash crop yield loss [22].

While it is well accepted that cash crop yield losses depend largely on cover crop species, cash crop yield losses average 5.5% for corn and 3.5% for soybean across the US Corn Belt from annual cover crops [23]. Such yield reductions likely result from constrictions in the timing of key field operations and from cover crop competition with the row crop. Although annual cover cropping has been adopted as a USDA Risk Management Agency (RMA) Good Farming Practice for crop insurance [24,25], specific NRCS Cover Crop Termination Guidelines reflect this risk, with termination guidelines to mitigate water competition between the non-irrigated cash crop and annual cover crop, plus general guidance on irrigated acreage [26].

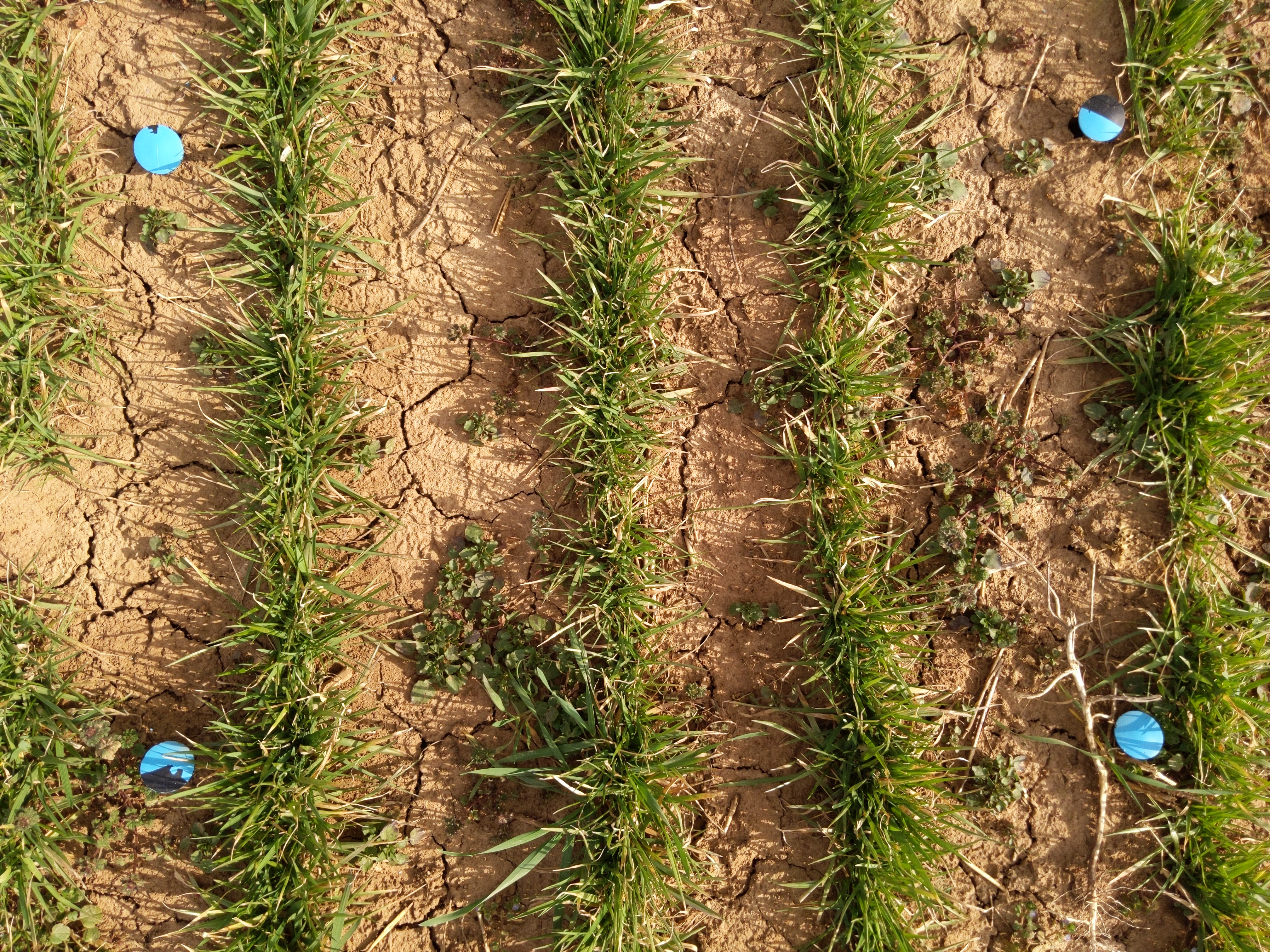

Perennial groundcover approaches (Figure 1) merge soil and water conservation with high-yield row crops [27]. The PGC system involves growing an annual row crop, like corn, with a low-growing, shallow-rooted, ecologically appropriate and compatible PGC, typically coupled with strip tillage [27,28,29,30,31,32,33,34]. The anticipated benefits of PGC are similar to the ubiquitous benefits of other year-round groundcovers: controlled soil erosion and soil health, improved soil structure [35], soil carbon sequestration [36], reduced nitrate leaching [37], and weed suppression [38]. The perennial nature of the groundcover in a PGC system delivers two key advantages: (1) the groundcover ecosystem service benefits are realized for multiple years from one planting event, and (2) the total number of field operations that are necessary to initiate and maintain a PGC system is significantly lower than that of annual cover cropping, meaning that the costs—including risk due to uncertainty—of PGC approaches can be lower.

For the past decade, the PGC approach for corn and soybeans has been tested in small plots and field trials using KBG and, more recently, improved varieties of Poa bulbosa (e.g., Radix Hybrid bulbosa, RHb Radix Evergreen, Aumsville, Oregon) [31]. The corn–KBG chemically suppressed PGC systems can produce corn yields that are equal to controls [32,33], but, at present, they pose a non-trivial yield risk because of potential competition between the row crop and groundcover. Furthermore, challenges of KBG establishment during drought years have been noted [39]. Based on this heightened risk, we assess KBG PGC to be at a Technology Readiness Level (TRL) of 4 [40], which implies that it is not yet ready for widespread adoption. The RHb is at an earlier TRL; thus, this paper focuses on the KBG PGC system.

In an effort to de-risk the KBG-PGC instance, which is highly relevant to the dominant Midwestern US cropping system, multiple dimensions of the challenge are being pursued, including (a) developing best management practices for managing corn in a KBG PGC system, including suppression chemistries and crop–PGC spacing; (b) screening for superior KBG varieties and for maize hybrids that are less sensitive to PGC; (c) examining the impacts of PGC on soil health and nutrient loss; (d) quantifying the ecosystem service potential derived from these systems using modeling approaches; and (e) understanding the socioeconomic and policy implications of PGC systems (https://www.regenpgc.org/ accessed on 13 August 2024). Directly related to the last of these avenues—and critical to the scalability of the corn–KBG PGC instance—is the potential economic performance of the system.

This work seeks to discern and make transparent the costs of implementing a corn–KBG PGC system, enabling comparisons of this emerging system to the dominant existing system. We hypothesize that optimized PGC systems can be cost-competitive with standard continuous corn (SCC). This work tests our hypothesis, elucidating key cost terms to help researchers better understand tradeoffs between different development pathways and identifying the most critical cost-roadblocks for broad system adoption. For that reason, this article provides background and summary information of expected production costs, revenues, and net returns comparing PGC and SCC, using an enterprise budget format.

Materials and Methods

Enterprise Budget and Budgeting Assumptions

We employ an enterprise budget to account for costs and returns for the corn–KBG system with suppressed KBG and SCC. Below, we describe the technical features of the system, highlighting the budgeting assumptions and rationale for the fixed and variable costs, yields, and revenues. We use the term standard row crop systems (e.g., continuous corn-on-corn, corn following soybeans) to describe the systems practiced on the vast majority of the US row crop landscape, which do not use cover cropping. For conservation practices to significantly improve ecosystem services, they must be adopted on large fractions of the working landscape. The values used in this analysis are therefore based on the emerging data and knowledge of the KBG–corn instance of a PGC system for Midwestern US producers, reflecting practices used by large-scale US corn production systems.

The KBG–corn PGC system assumes that corn is planted in alternating 38 cm (15-inch) tilled strips on 76 cm (30-inch) centers. The system has two distinct phases for field operations: (1) Year 1 is an establishment year, when the PGC is typically fall-planted, and (2) Year 2+ includes subsequent years, when the groundcover is established and requires management. The longevity of the perennial cover is uncertain and will likely vary based on species and site-specific factors; however, typical establishment will last at least 5 years and likely much longer until termination.

Corn production budgeting assumptions, as well as costs for field operations, labor, and land, reflect standard practices in the Upper Midwest [41]. The fixed and variable production cost data are primarily taken from the “Corn Following Corn” budget in Estimated Costs of Crop Production in Iowa–2024 (File A1-20) [41]. To supplement these assumptions, Iowa retail agribusinesses representing 50 locations were interviewed to determine the average herbicide costs for PGC and SCC, including both glyphosate- and non-glyphosate-tolerant conventional herbicide plants for the 2024 production year. The perennial groundcover seed cost estimates were provided by companies supplying KBG groundcover varieties specifically for the PGC system for the 2024 production year.

The primary fixed costs of production for both the KBG–corn PGC system and SCC include land cash rent equivalent, labor, and machinery-related ownership expenses such as depreciation, loan interest, and taxes. Variable costs include yearly input purchases that are needed to grow the row crop and machinery operating expenses. The budgeted cost and return estimates and expectations reflect the status of the PGC system development, and the default 204 bushels/acre (bu/ac) (12.8 Mg/ha) corn grain yield is based on the 30-year trend yield [41].

For both systems, the expected net return per acre (NRacre) is the difference between the revenue per acre (Revacre) and the sum of fixed costs and variable costs per acre of production (FCacre + VCacre). The revenue per acre (Revacre) is the product of the expected selling price for corn grain and stover (Pc, Ps) and the expected per-acre yield for corn grain (Buc) and stover (Tonss), respectively. Represented in equation form, these are determined as follows:

NRacre = Revacre − (FCacre + VCacre),

where

Revacre = (Pc × Buc) + (Ps × Tonss)

Optimistic and Pessimistic PGC Scenarios

The corn–KBG chemically suppressed PGC system has amassed approximately 26 site-years of published data thus far [28,29,30,31,32,33,34,39,42,43,44]. This relatively small data set introduces uncertainty of groundcover establishment success, field operations, and other key variables and, consequently, cost and revenue uncertainty. The KBG–corn enterprise budget therefore presents optimistic and pessimistic cost and revenue profiles utilizing the multiple year format, where expected costs, revenues, and net returns from a SCC system are compared with the same for the KBG–corn system in Year 1 and Year 2+. The enterprise budget consists of four KBG–corn system alternatives: Optimistic, Year 1, Optimistic Year 2+, Pessimistic Year 1, and Pessimistic Year 2+. The optimistic and pessimistic values reflect our best understanding of the potential range in PGC cost and revenue due to establishment success, field operations, and other key variables. The assumptions used to generate enterprise budget values for the PGC optimistic and pessimistic scenarios are summarized in Table 1 (see macro-enabled spreadsheet at www.regenpgc.org.

As is typical in enterprise budgeting, the fixed and variable costs differ for individual farms based on soil quality, location, management practices, and other factors. Thus, the enterprise budget utilizes averages for cost and revenue components to compare net returns for SCC and corn in a PGC system. In practice, the enterprise budget is provided as a starting point, with the ability to adjust cost components that reflect unique production situations

Differences in System Operations

Pre-Harvest Activities

The differences between SCC field operations and costs and those in the PGC system are largely concentrated in pre-harvest activities. The SCC budget assumes spring-time pre-harvest machinery expenses of chisel plowing, tandem disking, fertilizer application, field cultivating, planting, and spraying. The machinery requirements of PGC establishment include a no-till drill for groundcover planting in Year 1 and spring strip tillage in Year 2+. The primary cost of PGC establishment and adoption outlay occurs in the first system year with groundcover seeding. All other fieldwork and fertilizer amendments are basic operating costs for field prep prior to row crop planting [41].

Under an optimized system in Year 2+, a single strip tillage pass is sufficient for seed bed preparation and mechanical suppression of the perennial grass in the crop growth zone. An effective, banded herbicide application over the grass will eliminate the perception of light competition by the corn that results in corn yield loss. Mechanical suppression, such as strip tillage, is a companion suppression operation to reduce competition for nutrients and soil water within the crop zone. Under less optimal conditions, such as when rainy weather delays field work, cool season groundcover species may accumulate biomass rapidly, necessitating subsequent suppression with an additional strip tillage pass or herbicide application. The suppression efficacy can also be highly weather-dependent [29]. Several PGC management practices can be coupled with those of SCC systems in the spring, namely chemical suppression of groundcover with herbicides that also control weeds and mechanical suppression of groundcover with strip tillage that also prepares soil for corn planting. An optimized PGC system therefore includes fewer total spring field passes with strip tillage, fertilizer application, planting, and spraying.

Harvest Activities

Harvest activities are equivalent between PGC and SCC. In an optimized PGC system, researchers believe that almost all stover can be harvested within feedstock quality constraints, versus limited stover removal under SCC production, without additional field passes for chopping stalks, raking stalks, and baling stover. Therefore, the percentage of stover that is harvested in a PGC system will only be limited by machine capabilities. Stover operations should thus result in a higher net return under a PGC system versus SCC production.

Sensitivity Analysis

We completed a sensitivity analysis to compare SCC and corn in a PGC system. As recommended by Nelson et al. (2014) [45], we implemented a Monte Carlo simulation to evaluate the uncertainty in the differences between scenarios (see cost model and VBA Excel code for the Monte Carlo simulation, Appendix A). Using the static model, we determined that the following four terms drove the cost differences between the PGC and SCC scenarios: corn yield, herbicide cost, grass seed cost, and stover price. Using published 15-year historical data for these terms [46], we determined the coefficients of variation for each parameter. Although the corn price does not impact the cost differences between scenarios, we similarly estimated its coefficient of variation, allowing for simulation of these five key variables as normally distributed random variables with mean and standard deviations based on historical data for 1000 iterations in a Monte Carlo simulation.

Funding:

RegenPGC is supported by the Agriculture and Food Research Initiative Competitive Grant no. 2021-68012-35923 from the USDA National Institute of Food and Agriculture. Any opinions, findings, conclusions, or recommendations expressed in this article are those of the authors and do not necessarily reflect the view of the U.S. Department of Agriculture.